CLAY PIPE MAKING

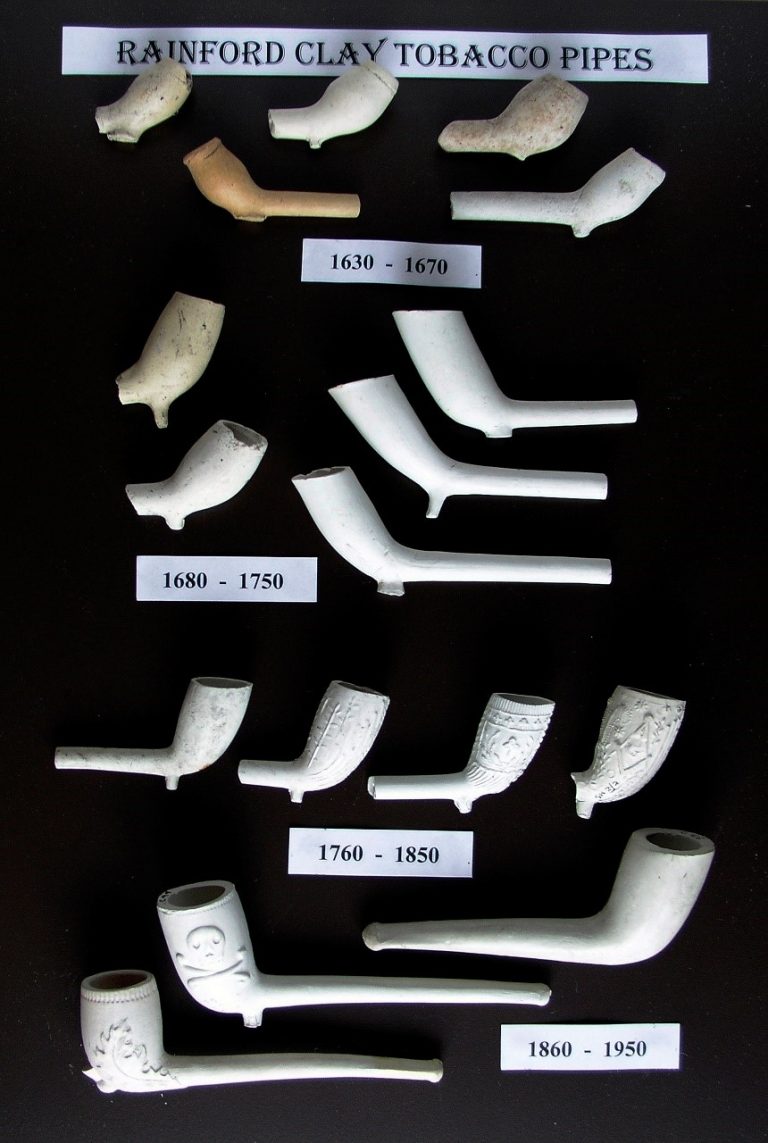

Soon after the introduction of tobacco at the end of the 16th century the manufacture of clay smoking pipes became established throughout the country. By about 1620 the clay potters and mug makers of Rainford had taken up this new trade, at first using clay dug locally but after 1700 using the finer white firing clay brought by sea from Devon & Cornwall.

Many of the early pipemakers combined the trade with farming but it is recorded that in 1696 twenty Rainford families were dependent upon pipe making for their livelihood. By the end of the 17th century Rainford had become well established as an important regional centre distributing its pipes over a wide area of the north west and beyond.

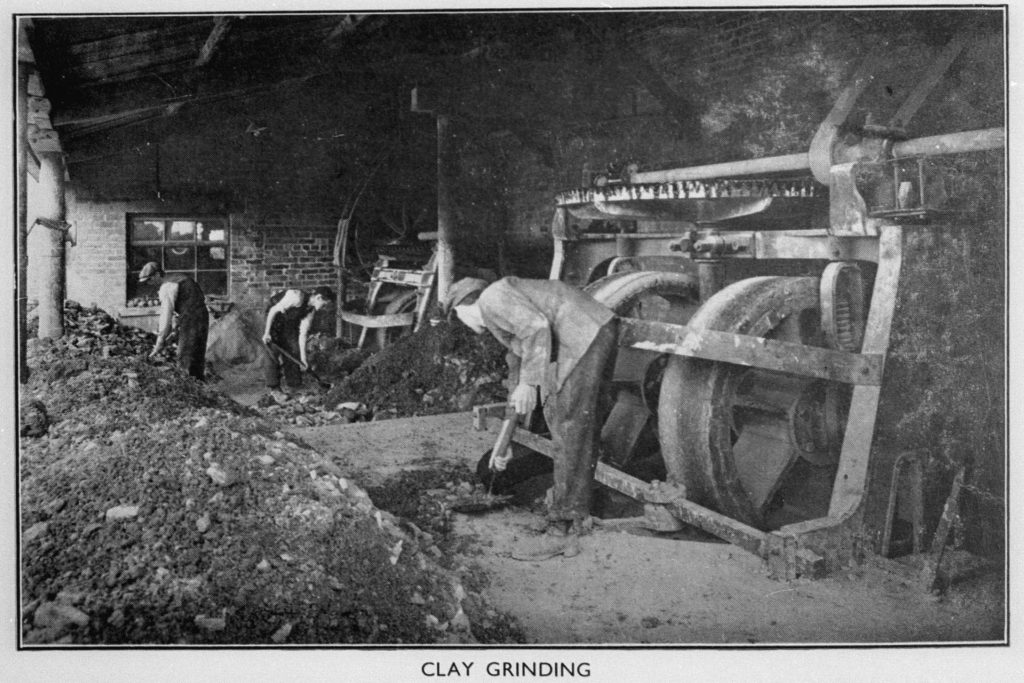

RANDLE BROOK PIPE WORKS IN ORMSKIRK ROAD

WORKERS AT RANDLE BROOK

The next century saw a decline in the industry nationally but the Rainford makers continued to prosper. By the middle of the 19th century production was at its peak with about 120 men and women employed in the industry, working mainly in small workshops throughout the village which had gradually superseded the farm based works of the 17th century.

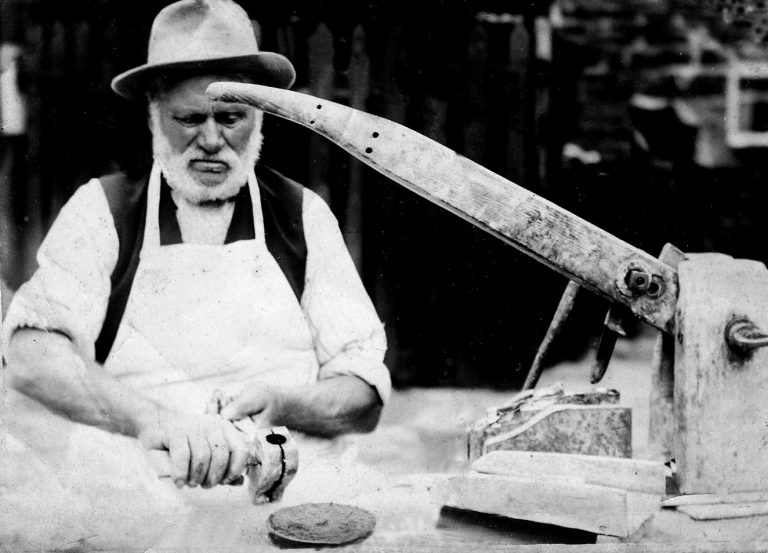

JOHN WINSTANLEY AT RANDLE BROOK

The introduction of the briar pipe, and later the cigarette, gradually reduced demand for the traditional clay pipes and the number of pipeshops fell from 14 in 1841 to 7 in 1883. A few of these works survived into the 20th century but one by one they ceased to operate and the last Rainford pipes were made at D. Swallow & Co.’s Hill Top Works in 1956.

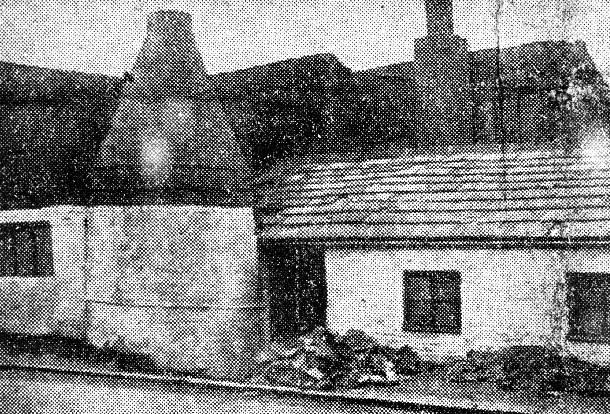

HILL TOP CLAY PIPE WORKS

William Smith 1781 – 1848 was the son of Isaac and Elizabeth Smith, pipemaker, at Moss Lane, Crank. William was the second of five sons and was named as ‘pipemaker’ at his marriage to Ellen Birchall in June 1802 and at the baptisms of his six children between 1803-1822. Where they were living is a little uncertain as around 1817 they would appear to have occupied “the Red Cat” near his father’s home in Crank. In 1824 William and Ellen are found occupying a site at Hill Top as a tenant under William Grayson and it is reasonable to assume that William had built his own pipeshop and cottage here. In Baines,1825, he is listed as a tobacco pipe manufacturer.

In 1824 William and Ellen Smith are found occupying a site at Hill Top as a tenant under William Grayson and it is reasonable to assume that William had built his own pipeshop and cottage here. In Baines,1825, he is listed as a tobacco pipe manufacturer.

In 1834 William and Ellen, together with their youngest daughter Jane left the cottage and took up residence at the “Bottle and Glass” an ancient public house some 100 yards to the north and thereafter William was also described as a publican. William died in 1848 followed by Ellen in 1851 leaving Jane their only unmarried daughter to carry on the trade.

Within three months after her mothers’ death Jane married David Swallow (1817 – 1885), Agent, and new to the area. By 1861 David had taken control of both the public house and the pipe works. The Swallow name remained until 1956 when the pipe works closed. After at least 300 years clay pipe making in Rainford came to an end.

DAVID SWALLOW TOBACCO PIPE MANUFACTURER

HILL TOP CLAY PIPE WORKS

HILL TOP CLAY PIPE WORKS

MRS MARIA FISHWICK HILL TOP PIPE WORKS

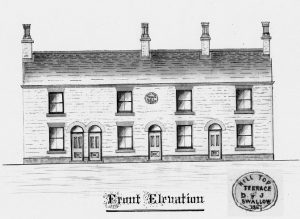

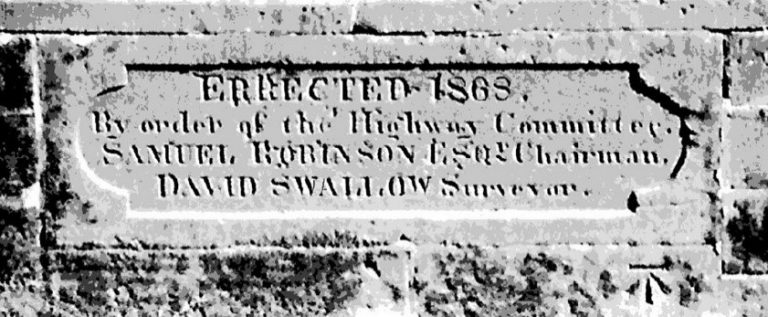

COTTAGES BUILT FOR DAVID AND JANE SWALLOW 1867

MILL LANE BRIDGE

PIPE WORKS CHURCH ROAD now RAINFORD LIBRARY

WORKERS AT CHURCH ROAD

PASTURE LANE PIPE WORKS

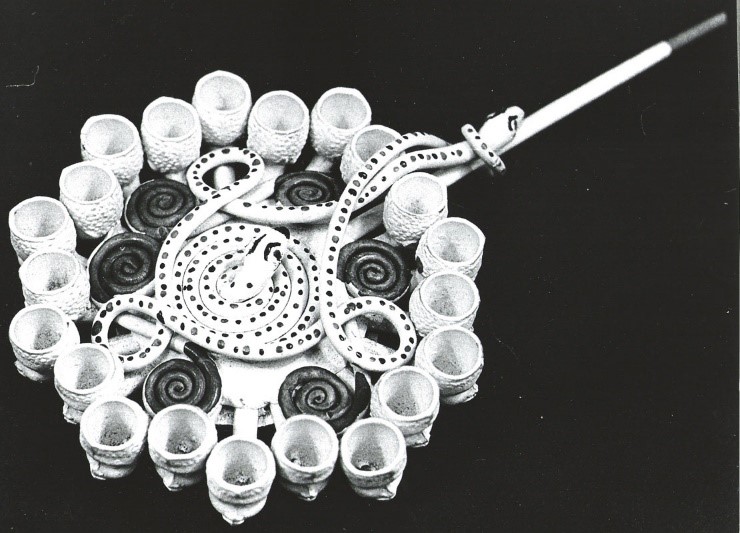

MOULDS FOR MAKING PIPES

DECORATIVE PIPE made at RANDLE BROOK PIPE WORKS

SELECTION OF PIPES MADE OVER THE CENTURIES

COAL MINING

With Rainford lying on the edge of the Wigan coalfield and having several shallow seams of coal near the surface it is very probable that coal was being extracted long before records were kept. Certainly by the end of the 17th century coal was being mined on a small scale from land known as John Barnes’s Tenement lying to the north of Bushey Lane. The Earl of Derby’s accounts for the year ending December 1765 include his dues for “what coals hath been got in by Joshua Berrington and Nicholas Moore since December 1755 in Barnes’s Pasture”; amounting to about 116 tons.Deep mining began in the late 1840’s with the opening up of two collieries at the north end of the village, the Rainford Colliery and the Victoria Colliery.

BUSHEY LANE SCHOOL originally COLLIERY WINDING HOUSE

RAINFORD COLLIERY

RAINFORD COLLIERY

Opened by William Harding with pits on the north side of Bushey Lane and later on the south side near the railway line where remains of the spoil heaps are still visible. The centre of the operation was at the site of the old Bushey Lane School which was originally the winding house for Numbers 7 & 8 pits with a rail connection to the Liverpool and Wigan railway line.

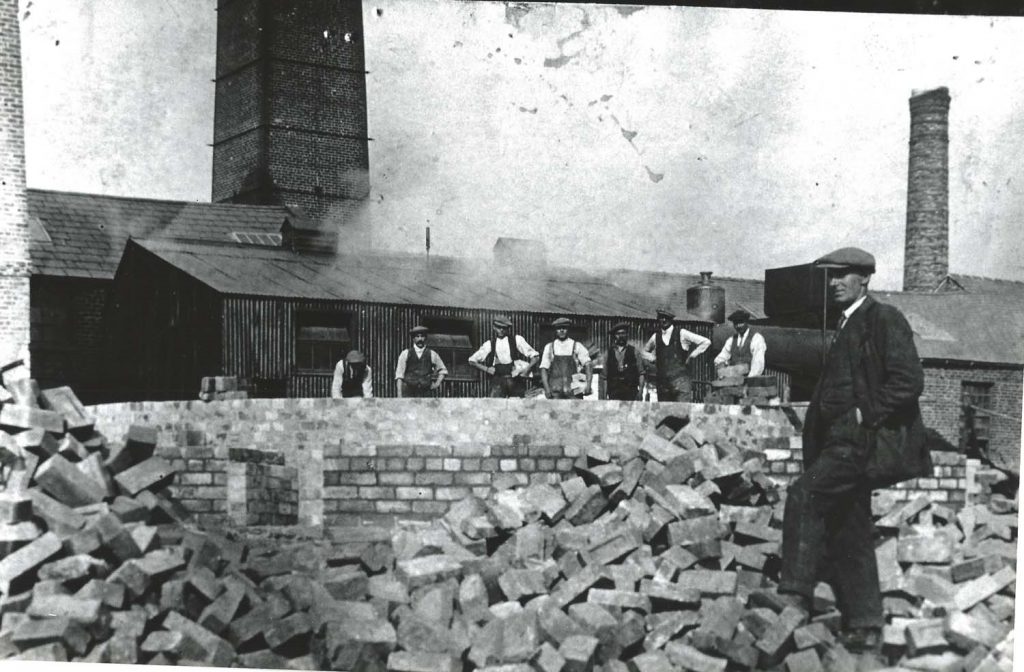

In 1857 the works were acquired by the Moss Hall Coal Company of Wigan who traded here as the Rainford Coal Company from at least 1868. In 1860 they sunk new pits further west at Siding Lane and by 1877 the original workings had been abandoned. Four pits at depths of 160 and 200 yards, a brick works and extensive railway sidings made this new colliery the largest in Rainford, employing some 580 men in 1894.

In 1903 the Company, then in liquidation, was taken over by Bromilow, Foster & Co. Ltd. who had mines at Bickerstaffe and St. Helens. The colliery finally closed after the General Strike in 1928.

VICTORIA COLLIERY

In February 1849 John and Thomas Birchall leased from the Earl of Derby a strip of land to form a tram road or railway from their land at the top end of Junction Road to the Liverpool and Wigan railway line with free liberty to convey coal raised out of their land. In December 1849 they leased this tram road together with the coal under their land to the firm of A. F. & D. Mackay & Company as the ‘Victoria Colliery’.

In 1852 the Mackay partnership was dissolved and the colliery, together with the ten dwelling houses on News Lane by the name of ‘Princes Terrace’ (later known as ‘Mackay’s Terrace’), was sold to the newly formed Victoria and Albert Coal Company. After several changes of ownership it was acquired by the Victoria Colliery Company in 1871.

By 1884 the new owners had sunk two new pits on the south side of Old Lane (at what is now ‘Parklands’) and laid a new railway connecting the two collieries to the Rainford and St. Helens railway line at the Village Station . The Junction Road site was eventually abandoned and the connecting railway and the branch to the Liverpool / Wigan line were dismantled.

VICTORIA COLLIERY VIEWED FROM OLD LANE

RAILWAY LINE ENTERING VICTORIA COLLIERY

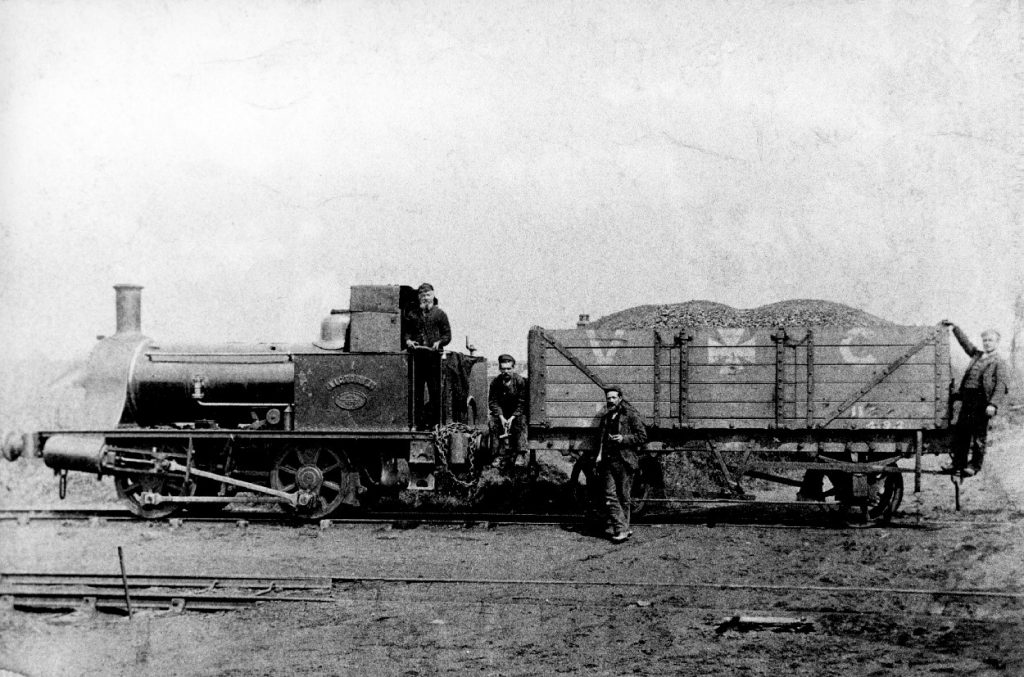

VICTORIA COLLIERY RAILWAY ENGINE

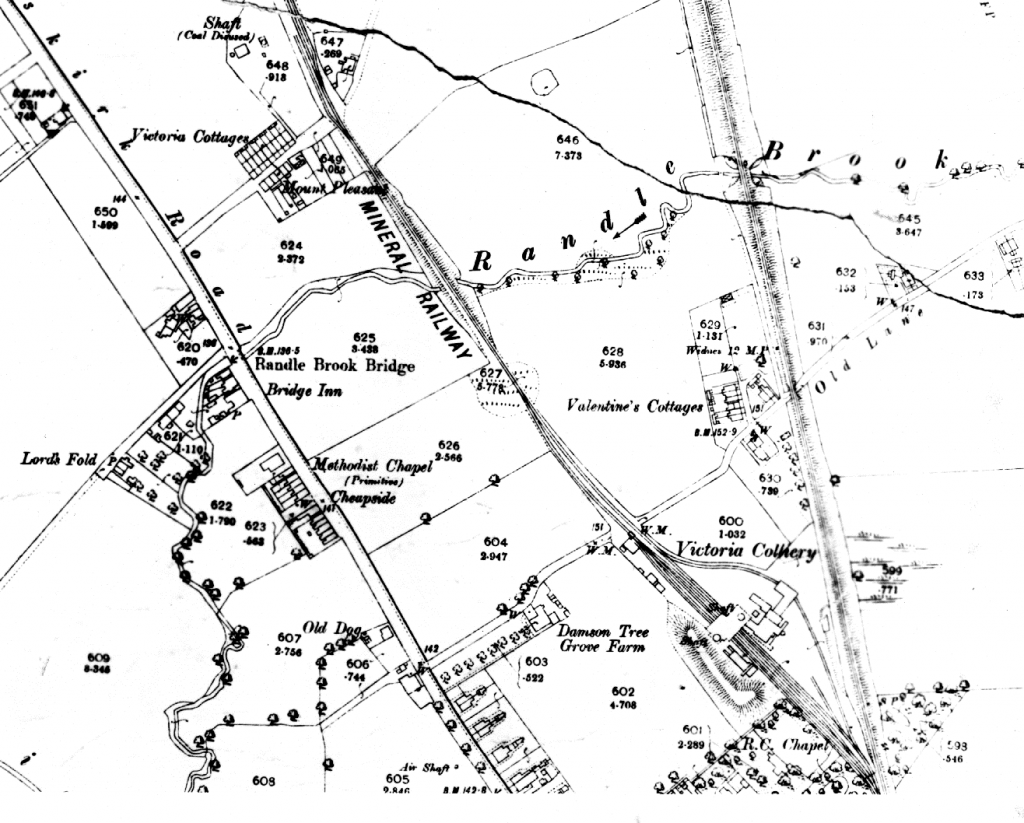

ORDNANCE SURVEY MAP 1909 SHOWING LINE INTO COLLIERY

THE AVENUE COLLIERY

Opened in 1929 in the fields between Ormskirk Road and the Brook this small colliery employed some 22 men. Lacking the usual shaft and headgear the workings, at a depth of 120 yards, were reached by an inclined tunnel down which the men walked to work and up which the laden coal tubs were drawn to the surface, a system known as a ‘day high’.

Following Nationalisation the mine was leased back to its private owners but soon after this it was closed down in 1952. The pit head site became a builder’s yard and is now covered by the houses of Cartwright Close.

THE AVENUE COLLIERY

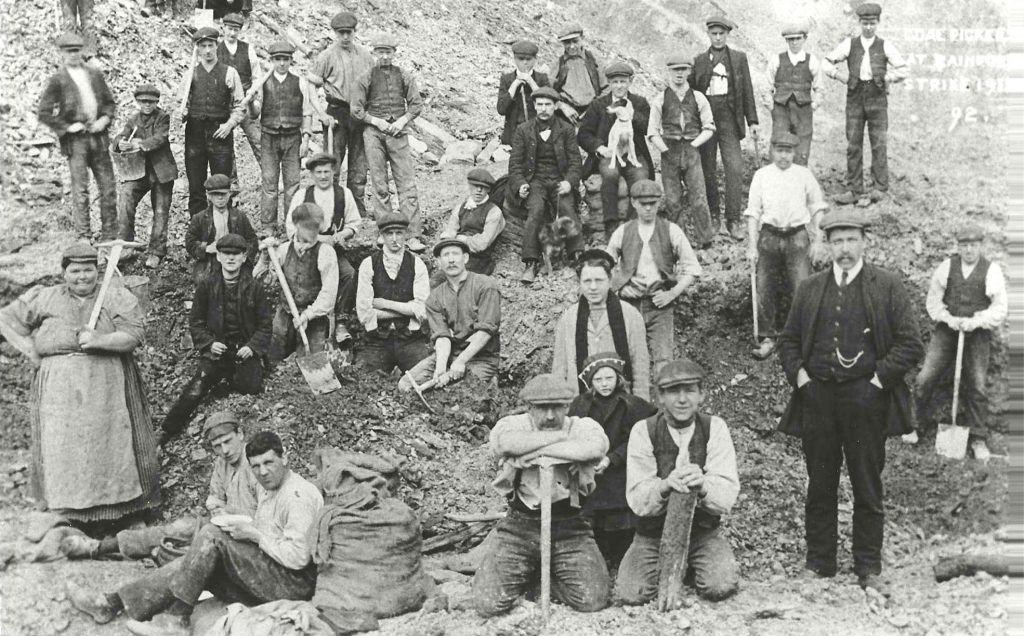

COAL PICKERS DURING STRIKE

1912 COAL STIKE

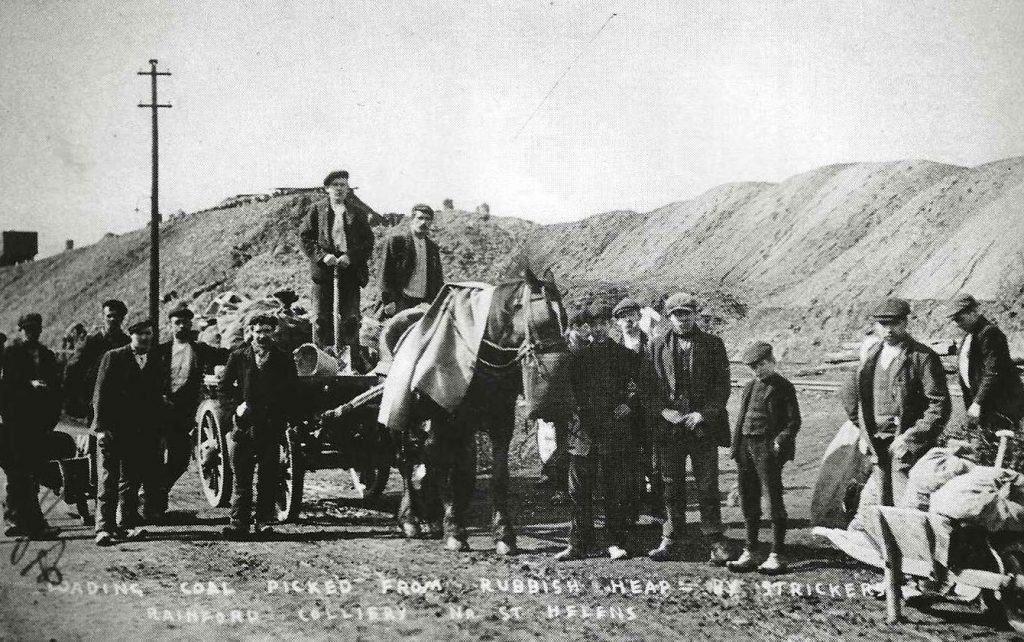

COAL PICKERS AT RAINFORD COLLIERY RUBBISH HEAPS

SEVERAL OTHER SMALL MINES EXISTED AT VARIOUS TIMES

MOSS HOUSE COLLIERY

Situated on the edge of the moss land between Langwood Lane and Kings Moss this small colliery was opened by 1865 by Messrs Horn & Kelly trading as the Moss House Colliery Company. In 1873 Thomas Bird and Company took over the workings and by 1888 the colliery was closed. Although only a small concern it did have its own railway with a single direction connection to the Liverpool / Wigan line near Red House Farm. No doubt the Colliers Arms public house in Kings Moss owes its name to this long forgotten colliery.

It had a brief moment of notoriety when twelve year old Ellen Hampson was fatally injured by a runaway wagon in the first half hour of her first day’s work at this colliery.

CRANK COLLIERY

Opened in the 1860’s at Berrington’s Lane near the boundary with Windle and worked from a single shaft. Coal was transported by a branch railway connecting with the Rainford to St. Helens line at Crank Station. Owned by Mr John Johnson and later the Crank Colliery Company the workings were finally closed in 1879.

HILL TOP COLLIERY

Coal was mined for a brief period in conjunction with the Rainford Potteries’ clay pit behind the Bottle & Glass Inn. Coal and fireclay were mined here between 1926 and its closure in 1934.

MILL LANE COLLIERY

Situated at the junction of Mill Lane and Higher Lane with shafts on both sides of Higher Lane this colliery appears to have been worked from the 1880’s until it was abandoned in 1913.

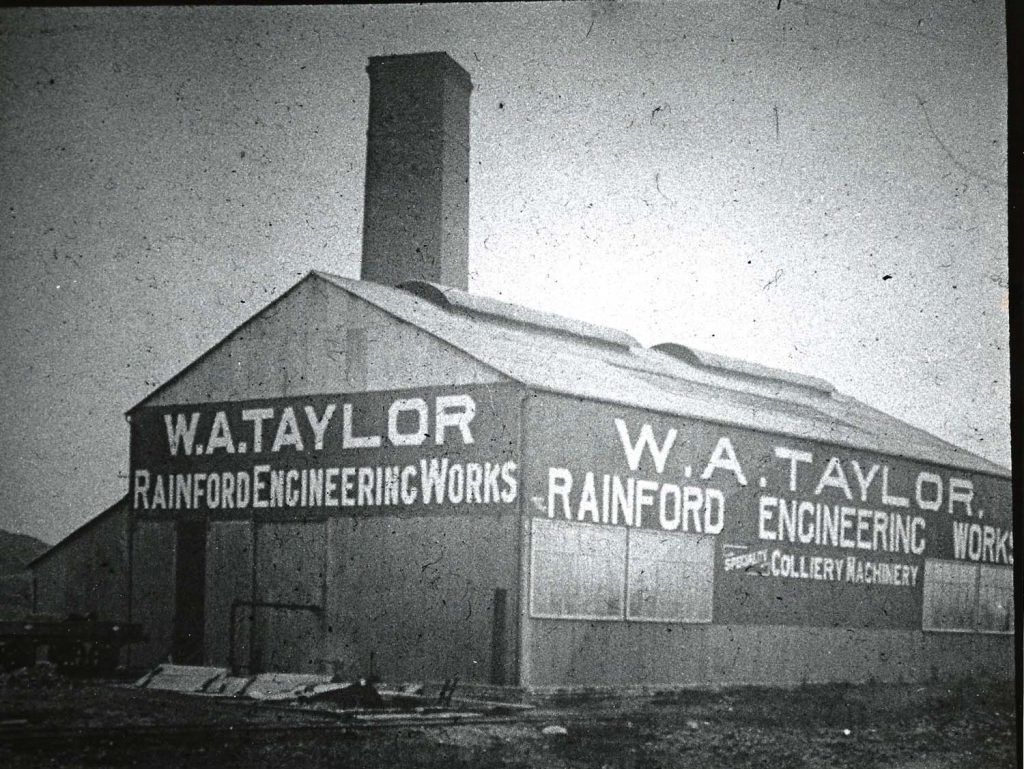

W.A.TAYLOR, RAINFORD ENGINEERING WORKS

It may have slightly preceded the Tar Works in Old Lane.

In about 1907 William Taylor arrived in Rainford to take up the management of the Rainford Engineering Works which stood close to Rainford Tar Works.

Plans were approved in September 1910 for a ‘New House for Mr W.A.Taylor ‘near the Old Lane’, (The Gap near the original Corpus Christi Church) and amended in April 1911.

Work additions for Messrs W.A.Taylor Ltd. were approved in November 1915.

From these planning applications it can be gleaned that the company appeared to continue after the death of Captain William Aloysius Taylor. Whilst serving with the 5th South Lancashire Regiment (T.F.) near Ypres, on the 9th May 1915 he received injuries to the spine and died 2 days later.

Captain Taylor was also a Director of Bickerstaffe Colliery.

This water pump in Penmaenmawr granite quarry North Wales made by W.A.Taylor. Rainford Engineering Works is still visible.

RAINFORD TAR WORKS

Following the closure of Victoria Colliery and Rainford Engineering Works, Rainford Tar Works occupied the site until a large fire on the 21st April 1942 in which three men lost their lives. Time was needed to clear the site before Robertson Buckley erected storage warehouses on what is now a housing estate known as Parklands.

STONE QUARRYING

Of Rainford’s natural resources which have been exploited over the centuries, stone is probably one of the earliest. Beds of good quality sandstone suitable for building or capable of being riven into roofing slates have been quarried and mined to build or cover many local buildings.

During the 1700’s the registers of Rainford Parish Church record over 40 men with occupations such as stone cutter, stone miner, delf man, scythestone maker and slate miner.

CRANK CAVERNS

SCYTHE STONE DELPH FARM

DELF COTTAGE

SCYTHE STONE DELPH

This quarry was situated on News Lane, between Hydes Brow and Maggotts Nook Road.

In 1715 William Holt inherited a house and land of about twenty seven acres from his father Hugh Holt. This would be Scythe Stone Delf farm house built in 1682 probably by Hugh’s father William Holt. In 1718 William leased the right to extract the rock or stone from certain fields on his land to Thomas Haydock of Rainford, stone mason. Shortly before he died in 1726 William sold the whole estate outright to Thomas Haydock for £500.

Thomas died without issue in 1729 and by his will he bequeathed all his estates to his brother James Haydock. As James was a shoemaker of Liverpool the farm and the delph were let out, possibly to James Grayson the husband of his sister Catherine and executor of the will. Two of James and Catherine’s sons were later described as scythestone makers.

James died without issue in 1752 and was buried at Rainford Chapel. By the terms of his will the Rainford estate eventually passed to the daughter of his niece Jane Heys.

By the 1840’s the estate appears to have been split up with Mary Briers, farmer, occupying the farm under a Mr Culshaw and Edward Ball, delf master, occuping the quarry under the Earl of Derby. The quarry had ceased to be worked by 1891 since when it has been flooded and now provides an ideal water for a local Angling Club.

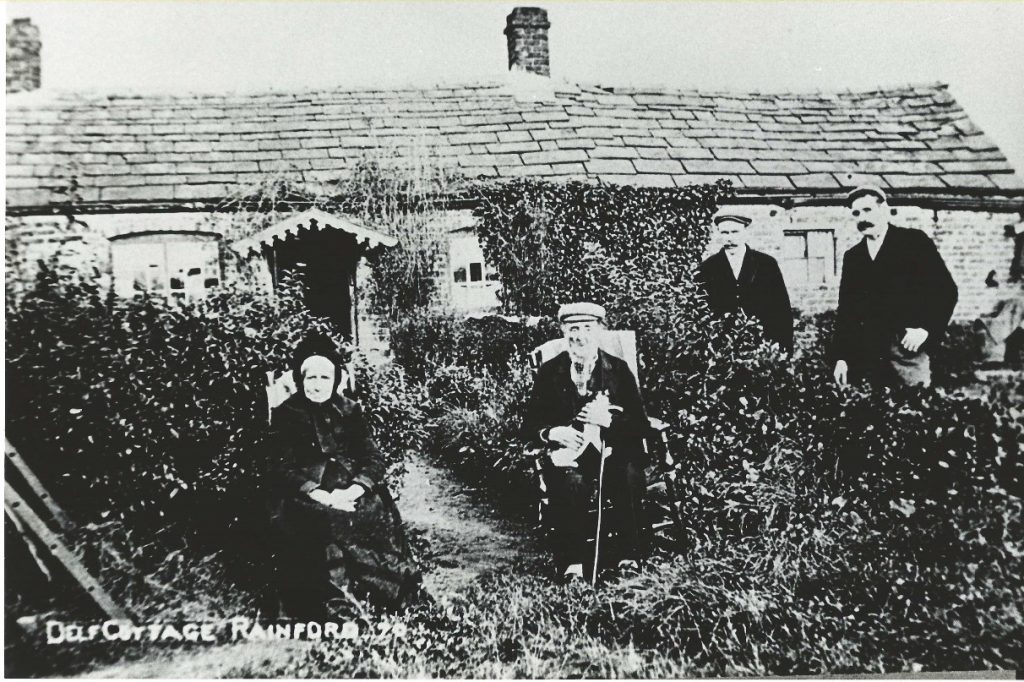

DELF COTTAGE

The home of Mr and Mrs Davenport and their sons. This old cottage was situated near the old stone quarry in News Lane not far from Mackies Terrace, the row of houses built c.1850 for the miners working at Victoria Colliery. The quarry was eventually filled with water and became a favourite haunt for local anglers. Mackies Terrace was demolished just over 100 years later and replaced by dormer bungalows known as Henderson Drive.

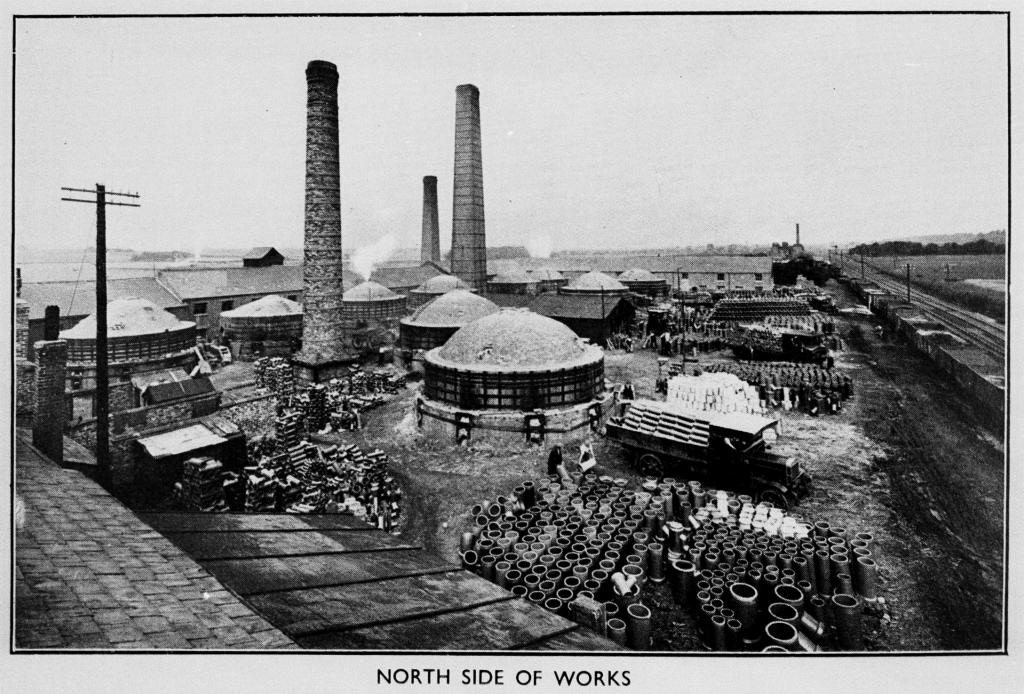

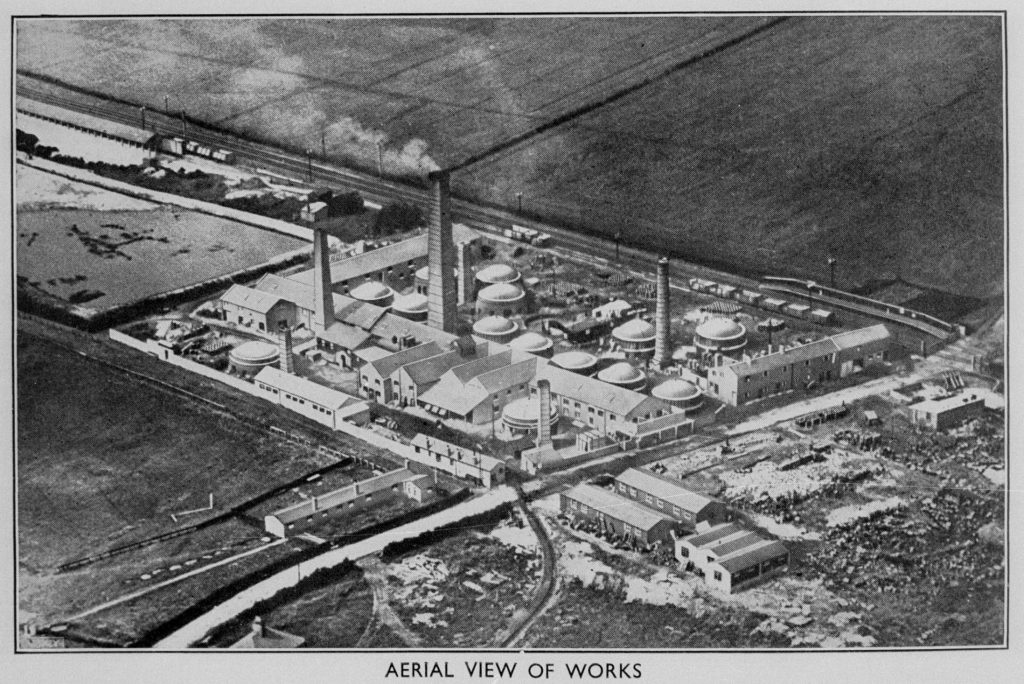

RAINFORD POTTERIES

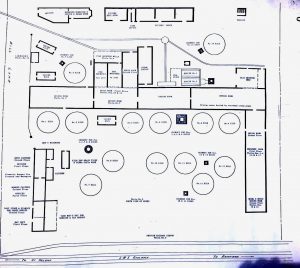

MAP OF POTTERY WORKS

RAINFORD POTTERIES LTD

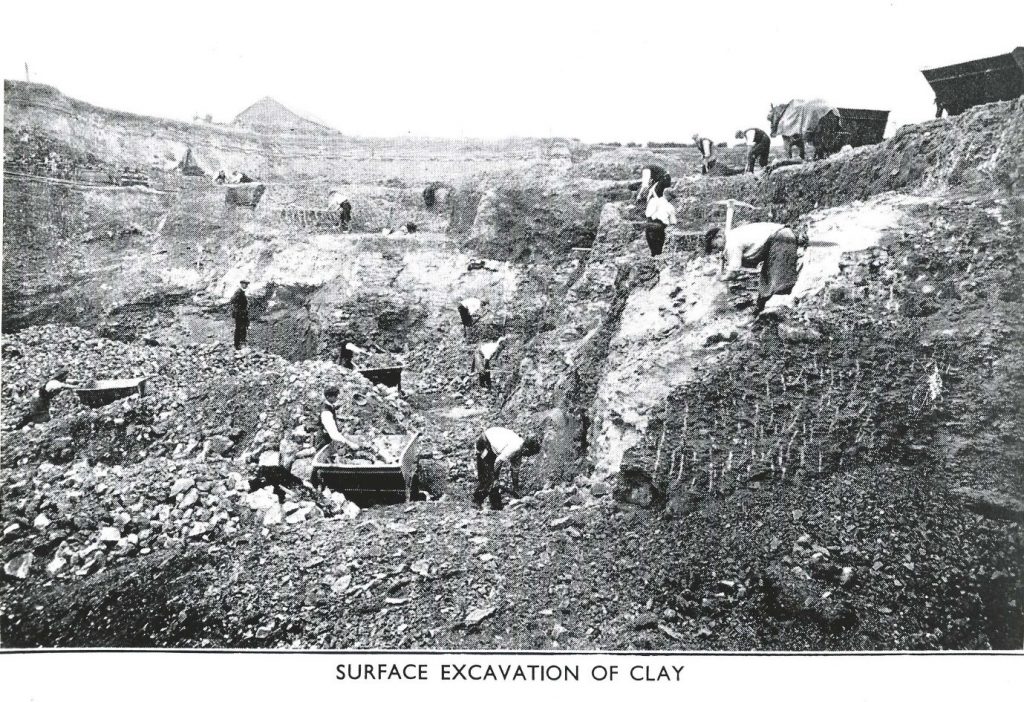

The exploitation of the natural beds of clay lying under Rainford has been going on for centuries. The clay potters or “muggers” and the tobacco pipe makers of the 17th century used the local clay deposits to good advantage. In the 18th century the commercial extraction of fire clay from the Earl of Derby’s land in the area around Fire Clay Farm found lucrative markets, first with the glass makers at Sutton, Liverpool, Prescot and Atherton, and later in the century with the copper works of Patten & Co.,Warrington, Roe & Co., Liverpool and Hughes & Co., St.Helens. The total weight of ‘finest black clay’ delivered to the copper works in 1790 amounted to 1440 tons at 8/- per ton.

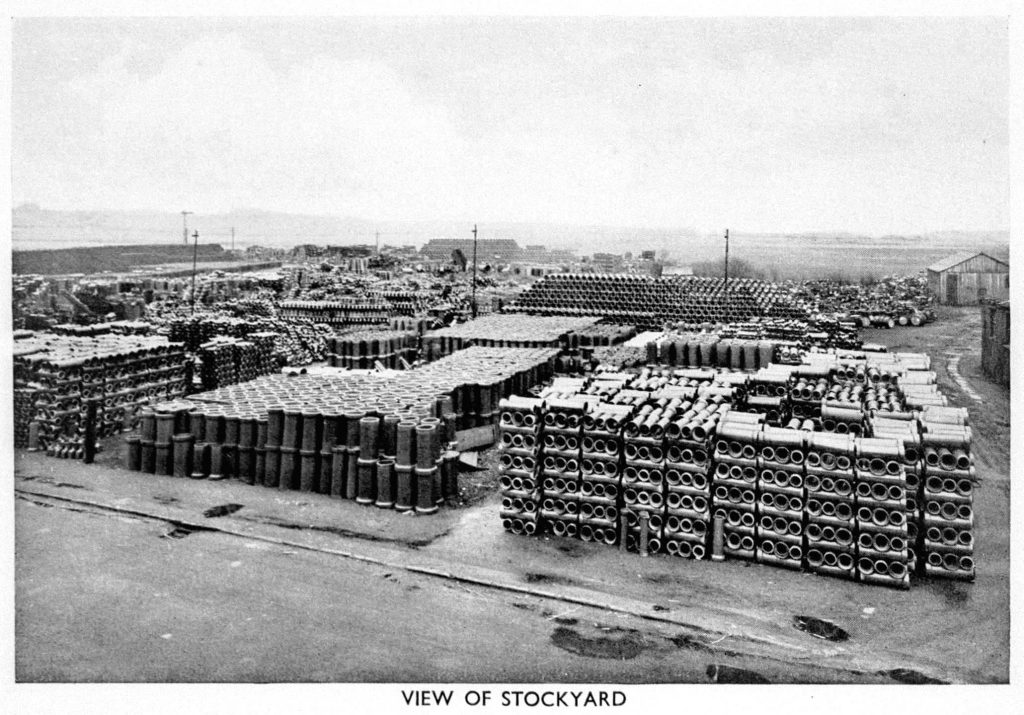

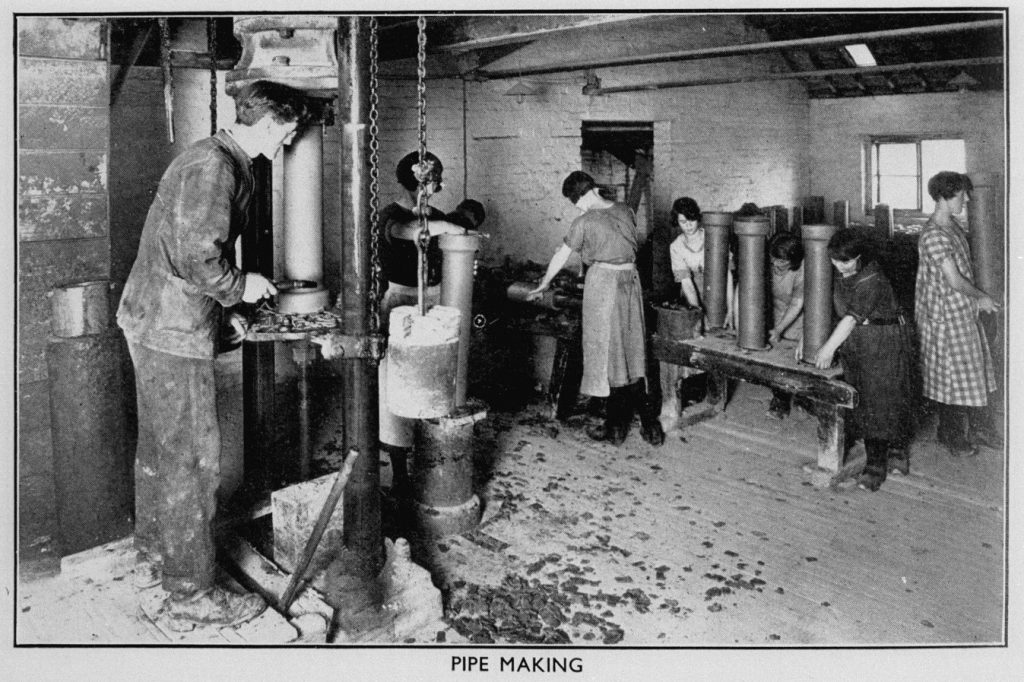

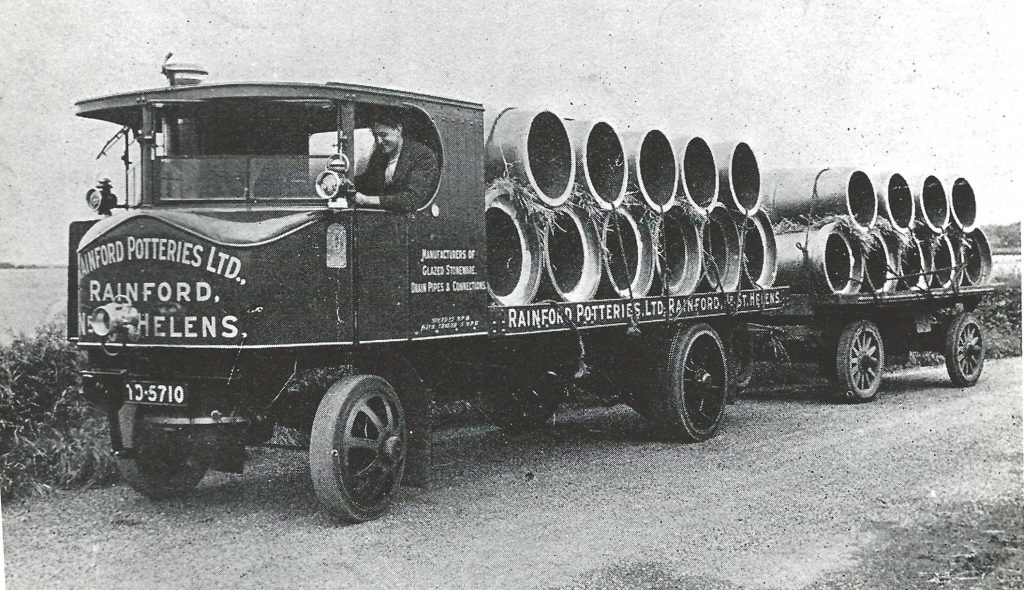

In 1868 the Mill Lane Mining Company, founded by the Grundy family, was involved in coal and clay mining which led to the establishment of works at Mill Lane for the manufacture of salt glazed stoneware drain pipes and fittings. They were the largest single clay users during the 19th and 20th centuries. In 1919 the name was changed to Rainford Potteries Limited. By 1907 their clay was being obtained from a large opencast clay pit behind the Bottle & Glass Inn and transported to the works by a narrow gauge, horse drawn railway.

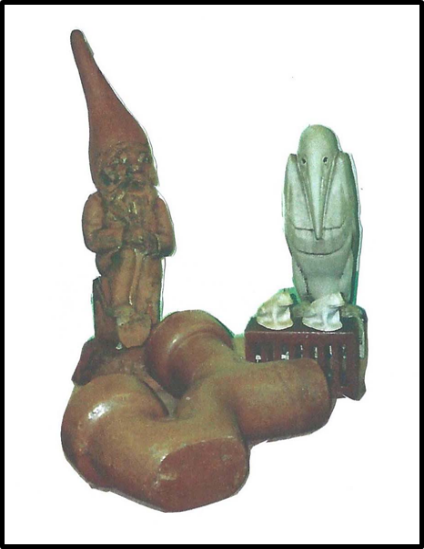

In addition to a vast range of drain pipes and fittings the company also produced chimney pots, troughs, sinks etc. and later ventured into terra cotta and faience products for the building industry. A side line to their main business was the manufacture of garden gnomes and other garden ornaments. As one of the largest employers in the village they provided much needed sporting facilities by way of football teams, cricket teams and sports meetings. Annual outings and their own brass band continued for many years.

CHIMNEY POTS AND UMBRELLA STANDS

DRAIN PIPES AND DECORATIVE GARDEN ORNAMENTS

ENTRANCE INTO POTTERIES

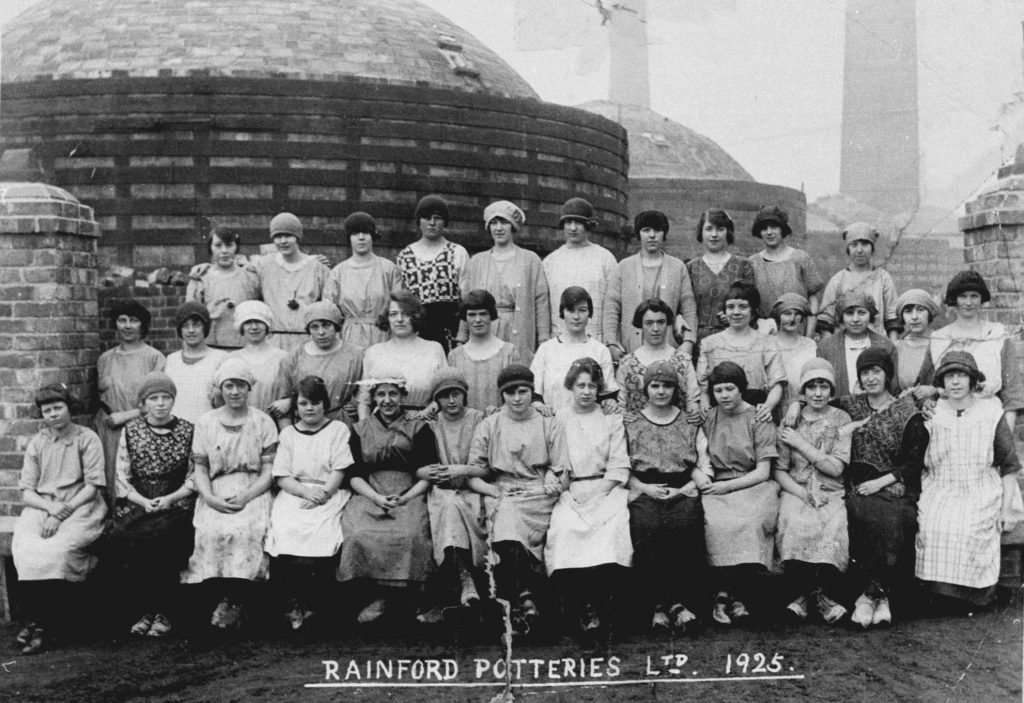

POTTERY WORKERS 1925

POTTERIES LORRY

In the face of increasing competition and modern developments in new types of drainage goods the company went into voluntary liquidation in February 1970. The kilns and chimneys have disappeared but many of the old buildings still remain, now occupied by various small industrial units.

RAINFORD SANDWASH

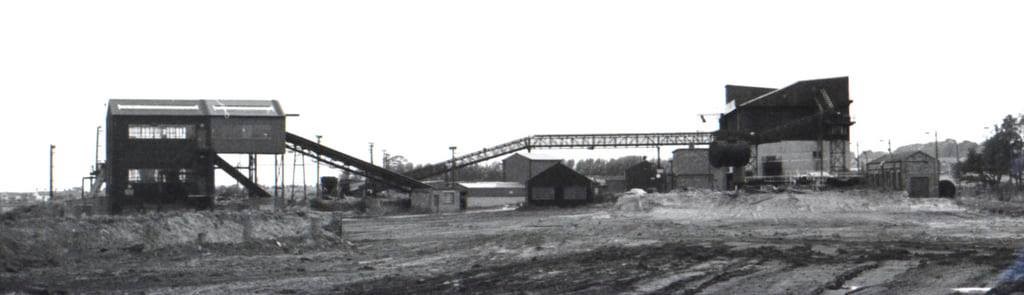

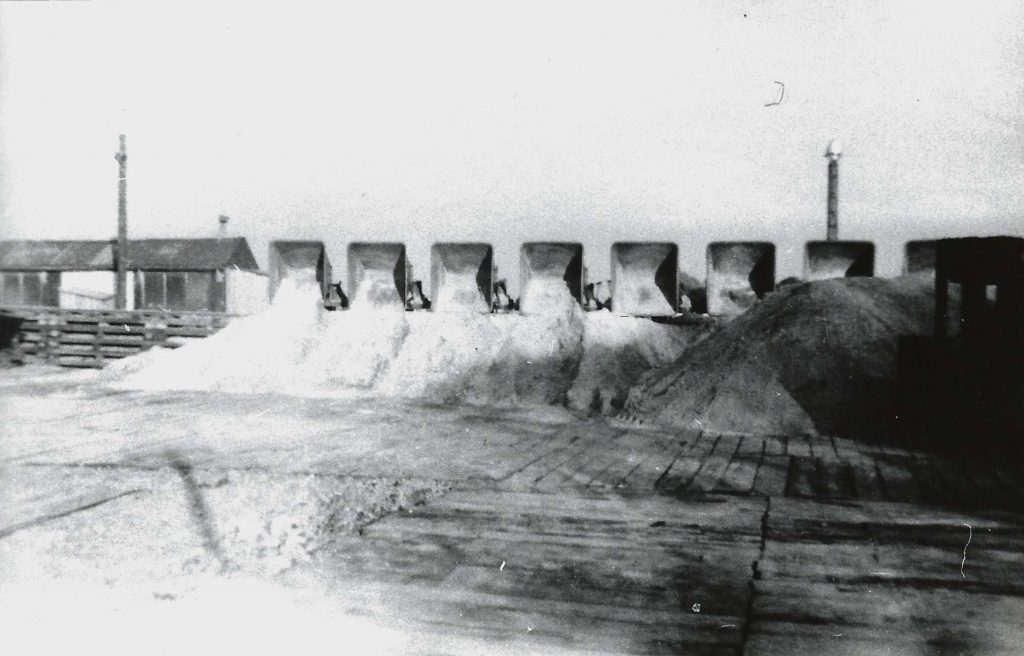

SIDE VIEW OF SANDWASH LOOKING TOWARDS ROOKERY LANE

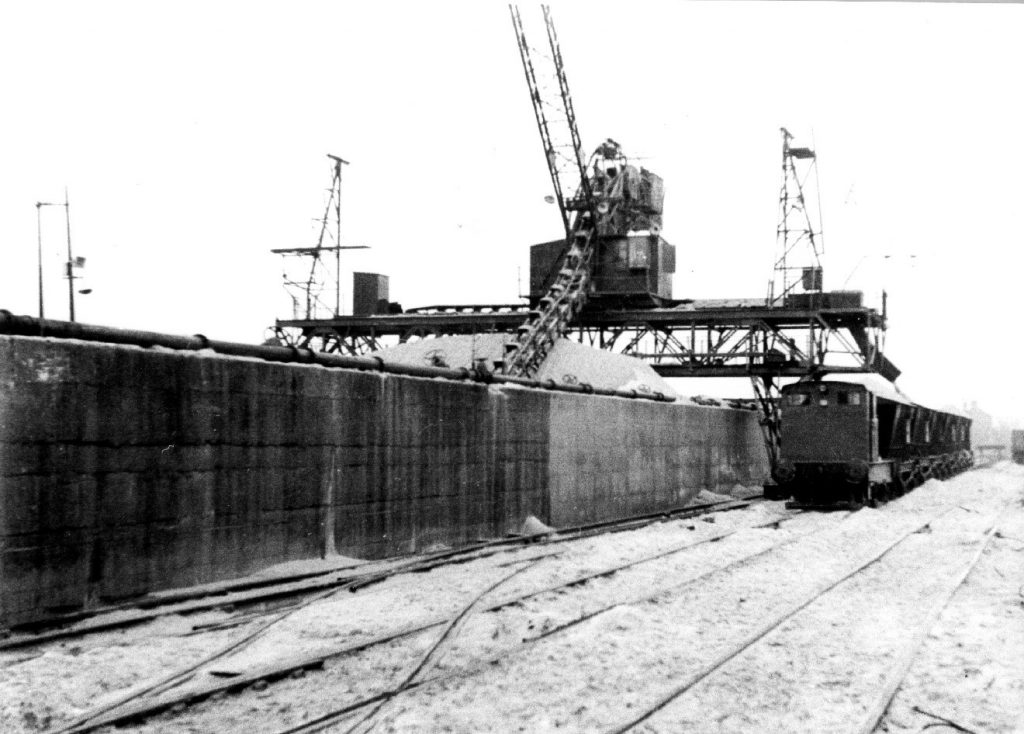

Beneath the soil of many fields in Rainford lies a bed of yellow-brown sand ideally suited to the manufacture of glass. Pilkington Brothers had been manufacturing window glass in St. Helens since 1826 using sand carted directly to the works from local fields but when this became insufficient for the increased production they looked further afield to Rainford. In 1880 a railway siding was laid from the Rainford to St. Helens line to a site just north of Mill Lane where sand from the immediate area was conveyed by horse drawn narrow gauge tramways and transhipped into standard gauge railway wagons for delivery direct to the glass works.

MAIN ENTRANCE

POTTERY PADS TOWARDS MILL LANE

MAIN ENTRANCE

In 1881 a sand washing plant was built at this railway siding and over the next twenty years the tramway system was laid, removed and re-laid to reach sand fields firstly over Pasture Lane to fields beyond Reeds Lane, then over Mossborough Lane to fields around Moss Nook and finally over Rookery Lane to fields between Church Road and the Railway. In 1904 a new tramway system using trucks hauled by wire rope was laid from the Sand Wash, across Mill Lane and alongside the brook towards Crank Station. This system and branches from it was in operation until the 1930’s.

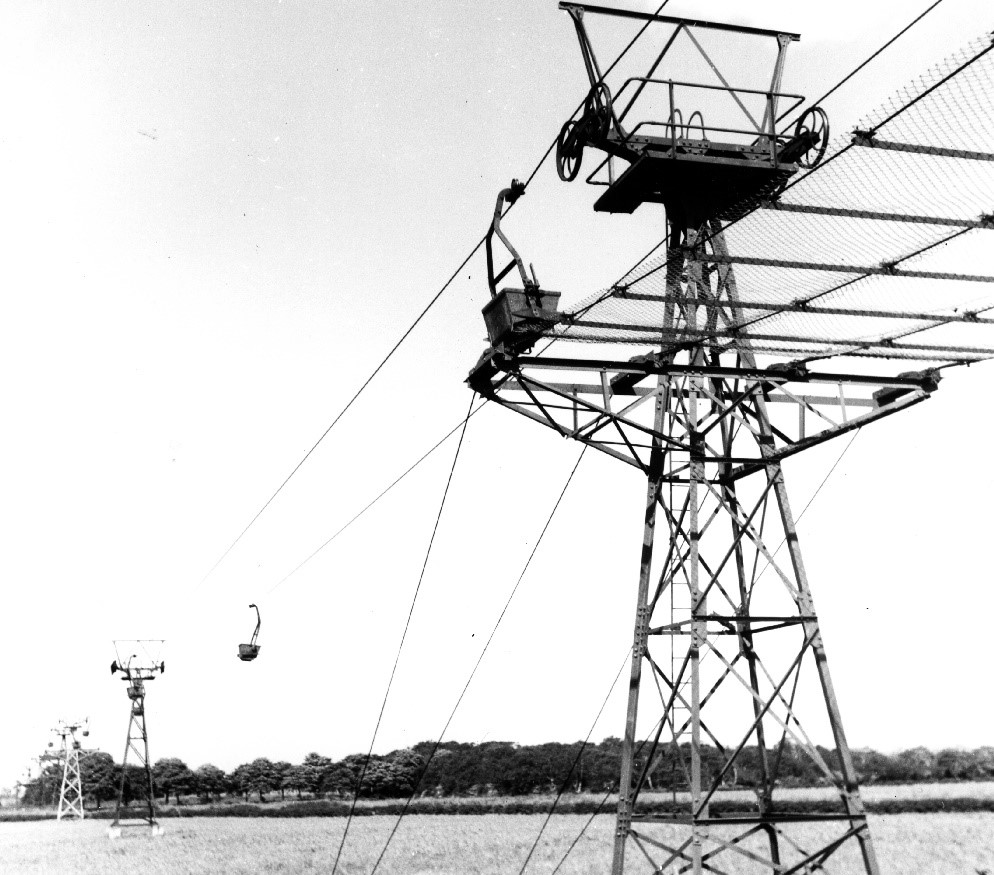

In 1931 an aerial ropeway was constructed running north east from the Sand Wash, crossing over Higher Lane to a terminal building near Myers Farm to serve new sand fields around Kings Moss. At the terminal the buckets were transferred to narrow gauge railways, hauled to the various fields by Diesel locomotives, filled and returned to the ropeway. Using multiple buckets carrying up to 15 cwts each this system was capable of transporting 2000 tons of sand per week. This ropeway supplied the Sand Wash until 1946 when it was dismantle.

THE SAND HEAPS

DRAINAGE BINS

THE ROPEWAY

PASSING OVER THE BY-PASS

With the Kings Moss sand fields being exhausted an aerial ropeway was built in the opposite direction, passing over the new Rainford By-pass to reach new sand fields at Moss Lane in Windle. In 1950 the ropeway was extended from this terminal, over Blindfoot Lane and terminating at Sandy Brow Farm on the edge of the Kirkby Industrial Estate.

The Kirkby sand was worked out in 1955 and the ropeway was dismantled back to the Moss Lane terminal from where a new extension was erected, passing over the East Lanc’s Road to a terminal on the east of Catchdale Moss Lane. The final extension in 1957 carried the ropeway over Catchdale Moss Lane to a loading station near Rainford’s Farm. Throughout the 1950’s the annual production of sand amounted to over 200,000 tons. In 1960 the ropeway system was abandoned altogether and thereafter sand was transported by lorries from the various sand fields, now lying as far out as Ormskirk, Bickerstaffe and Skelmersdale, to the Sand Wash in Mill Lane.

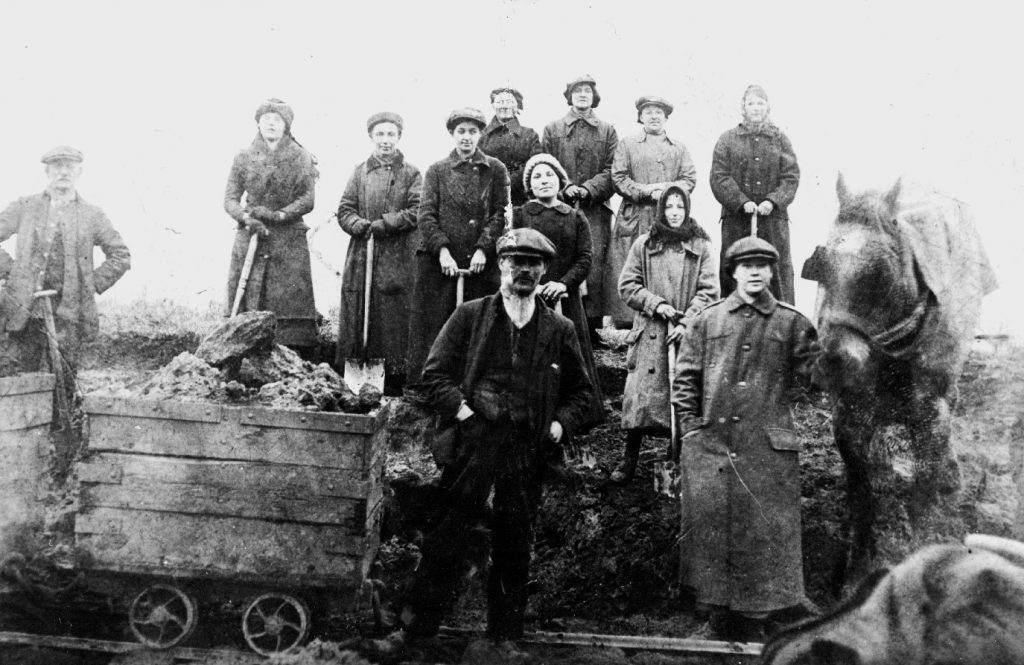

WORKERS GETTING SAND

SAND EXTRACTION NEAR NEWS LANE

SANDWASH LADIES

The original timber sand washing building was destroyed by fire in 1963 and a new concrete building soon replaced it. Rail transport was still used to carry the washed and blended sand to the glass works until January 1967 after which the last remaining section of the railway from Mill Lane to St. Helens was dismantled.

Sand getting locally was scaled down during the 1970’s and in January 1978 the last load of sand was carted from Bickerstaffe to the Rainford Sand Wash. After all the sand on stock had been washed and delivered the plant was finally closed down in March 1978, ending almost 100 years of sand working in Rainford. The Sand Wash site has since be developed into a small industrial estate.

FARMING

Farming has always been an important element in the life and economy of Rainford from earliest times when some livestock and a small acreage of arable land were essential for a self sufficient household.

The draining and improvement of large areas of the moss land to the west and east of the village from early in the 18th century increased the usable acreage resulting in larger farms able to produce a surplus to their own requirements which could be sold.

From the Population Census taken in 1841 we can calculate that 47% of the inhabitants of Rainford depended on agriculture for their livelihood. This does not take account of supporting trades such as blacksmiths, wheelwrights, carters, etc., nor the casual labour employed at busy times.

Mechanisation of the industry has drastically reduced the numbers employed on the farms which have themselves been reduced in numbers from 84 in the mid 1800’s to 29 at the present day. Housing estates, roads, schools etc. have reduced the total area of agricultural land but despite this contraction Rainford is still considered a farming area.

The timeless cycle of the farmer’s seasons, whilst not dominating all our lives, cannot pass unnoticed by the residents of the village.

REEDS FARM

MOSS NOOK FARM now known as INGLENOOK FARM

HARVEST TIME AT KERFOOTS FARM

POTATOES STORED FOR WINTER

THRESHING TIME AT RED DELPH FARM

VARIOUS OLD TRADES